A step by step guide through the process of designing a whole house ventilation system.

With Mechanical Ventilation with Heat Recovery (MVHR) increasingly becoming the ventilation system of choice for new build projects, contractors need to be familiar with the design and specification of whole house ventilation technologies. National Ventilation specialises in offering a full design service including quotations, unit calculations, a full kit list, recommended duct routes, as well as ensuring that it meets building regulations.

These are the 9 steps that we take to design and specify a ventilation system for you:

Step 1 – The first step in designing a ventilation system is obtaining the architects drawings in order to specify the correctly sized ventilation unit and the correct type and lengths of ducting – whilst ensuring it complies with Building Regulations. National Ventilation works with the contractor to design a system that will provide the correct levels of ventilation and would physically work within the structure. Step 2 – Next, National Ventilation looks at the architect drawings and the property details, including room dimensions, and enters these details into an airflow calculator. This ensures the ventilation specified meets the airflow demands of each room.

Step 2 – Next, National Ventilation looks at the architect drawings and the property details, including room dimensions, and enters these details into an airflow calculator. This ensures the ventilation specified meets the airflow demands of each room.

Step 3 – Once the total airflow figure is calculated an MVHR unit is selected to improve indoor air quality and reduce space heating costs. National Ventilation has a full range of MVHR units available and designs the systems so the unit is never working at more than 75% of its maximum capacity which helps ensure it works quietly and efficiently. Our range of units include the new Monsoon Energysaver™ IntelliSystem Heat Recovery Unit with touch screen and app control for easy installation, plus the Monsoon Energysaver™ MON-HRU Heat Recovery Range, which offers up to 94% heat recovery efficiency. Step 4 – The next step in ventilation design is to decide where best to locate the MVHR unit. Often it can be located in a loft, however, if there are vaulted ceilings an alternative location is needed, such as a utility room.

Step 4 – The next step in ventilation design is to decide where best to locate the MVHR unit. Often it can be located in a loft, however, if there are vaulted ceilings an alternative location is needed, such as a utility room.

Step 5 – Next it is important to work out where to locate risers and ducting. When designing the ventilation for the property, National Ventilation talks to the contractor about where to run the ducting. If there are vaulted ceilings there will be no ceiling voids to run ducting. As an alternative ducting can be run through webbed eco joists, however, if this is not an option National Ventilation would discuss with the contractor other solutions such as running the ducting between floors or within stud walls.

Step 6 – Having decided on ducting location, the next step is to decide whether to use rigid or semi-rigid ducting. Semi rigid ductwork, such as National Ventilation’s Monsoon Radial ducting, is ideal for smaller developments since it is flexible, robust and up to 60% quicker to install. This type of ducting also means fewer mistakes, since even a novice can Install it to a high standard, resulting in an airtight installation and Improving system performance. With a plethora of plenums and accessories this system can overcome over 99% of issues that may occur on-site.

Step 7 – The next step is consider controls. Traditionally MVHR is often boosted on bathroom lighting, however, not every bathroom visit is a shower or a bath and so systems can boost unnecessarily. As an alternative National Ventilation therefore offers a more efficient control method with an in-duct humidistat fitted in the ducting which means the boosts only triggers when humidity rises. An in-duct humidistat also takes less time to install and is more costeffective as less wiring is needed to install it since electricians only need to wire the humidistat back to the fan because the fan is constantly on, drawing air from the bathroom.

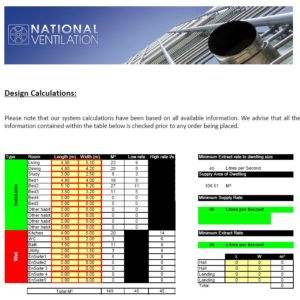

Step 8 – Once the initial design is complete National Ventilation will send the design and quote to the contractor’s electrical wholesaler. This is supplied with detailed calculations, proposed ducting layout, where to put the MVHR unit and risers and how to control the unit.

Step 9 – However, although a design may appear correct on paper it is vital to ensure a design works on-site. Quite often architect plans only tell half the story and contractors can often be caught out if things such as steels don’t show up on the original plans. The knock-on effect of this can be a need for additional materials that haven’t been considered in the original calculations. National Ventilation’s BPEC accredited project managers therefore carry out a free pre-order site visit to ensure the design will perform as Intended. This visit is a great trouble shooting exercise and Is also a good opportunity for the electrical contractor to learn more about the Installation process. By using a free planning and advice service, such as the one offered by National Ventilation, electrical contractors can be safe In the knowledge that they are Installing a well-designed system and will have a point of contact that will assist them throughout the whole job.

Please contact us for more information about the planning and advice services on offer from National Ventilation. Click here to download our free step-by-step guide.